HYBRID COMPONENTS REDUCE COSTS AND INCREASE THE QUALITY OF YOUR END PRODUCTS

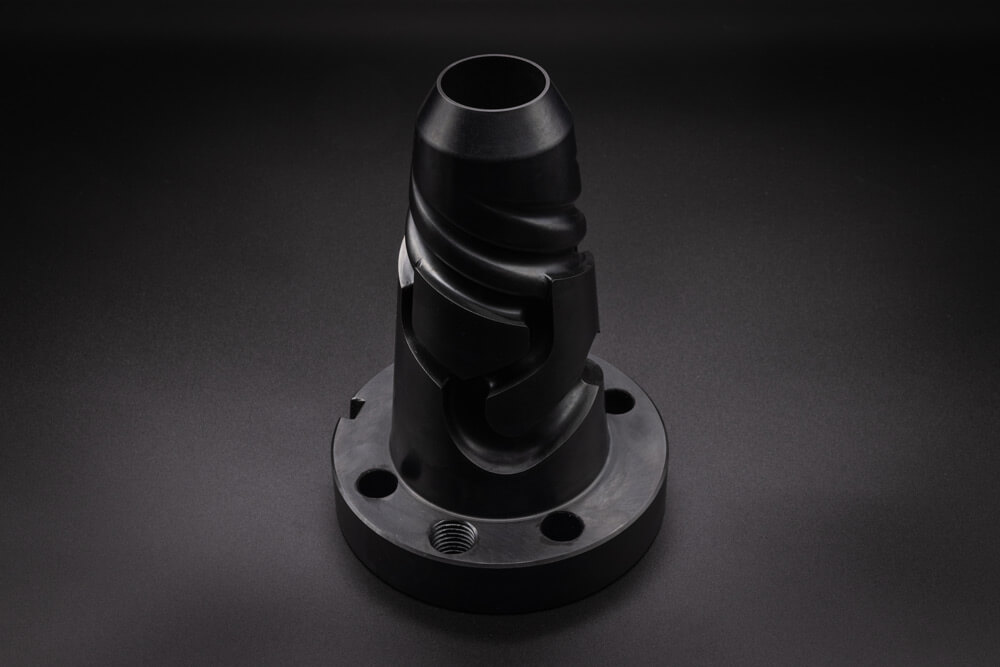

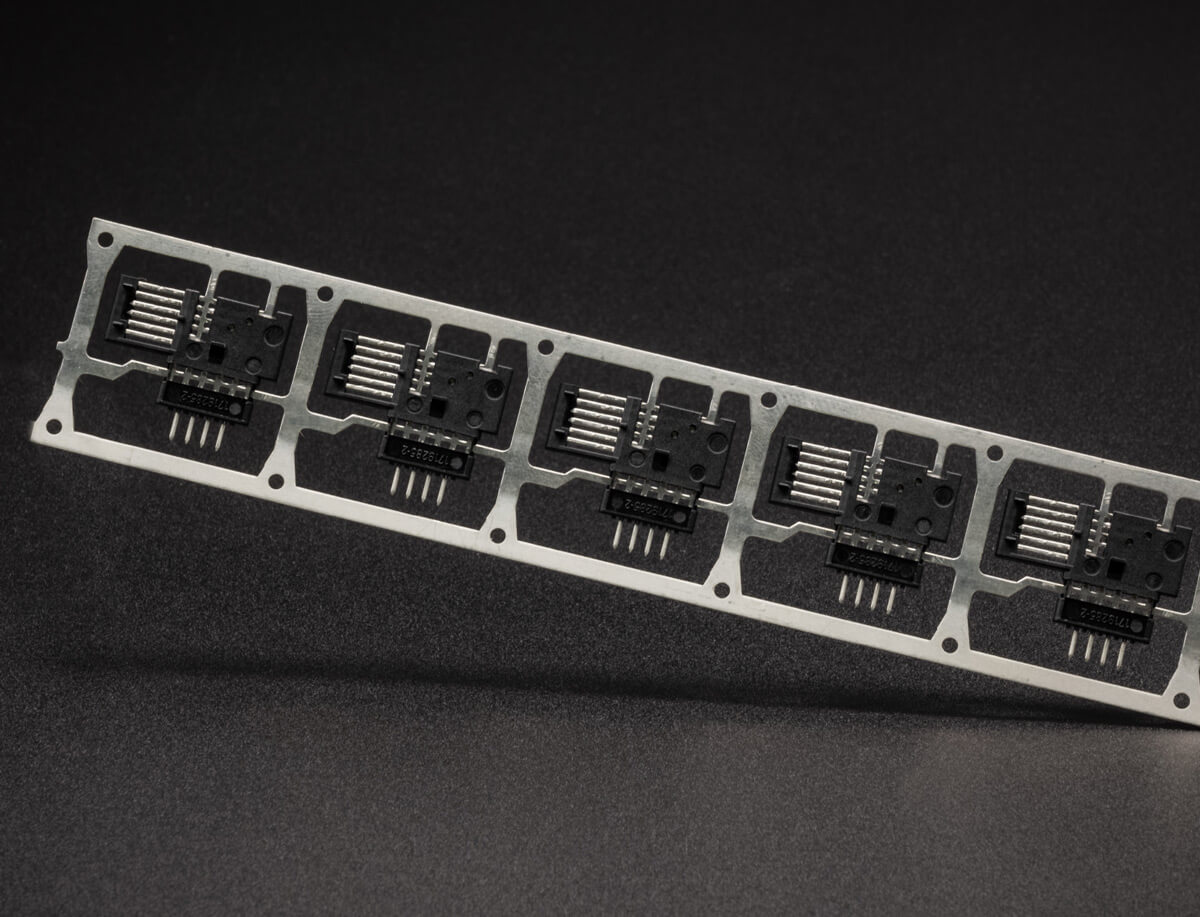

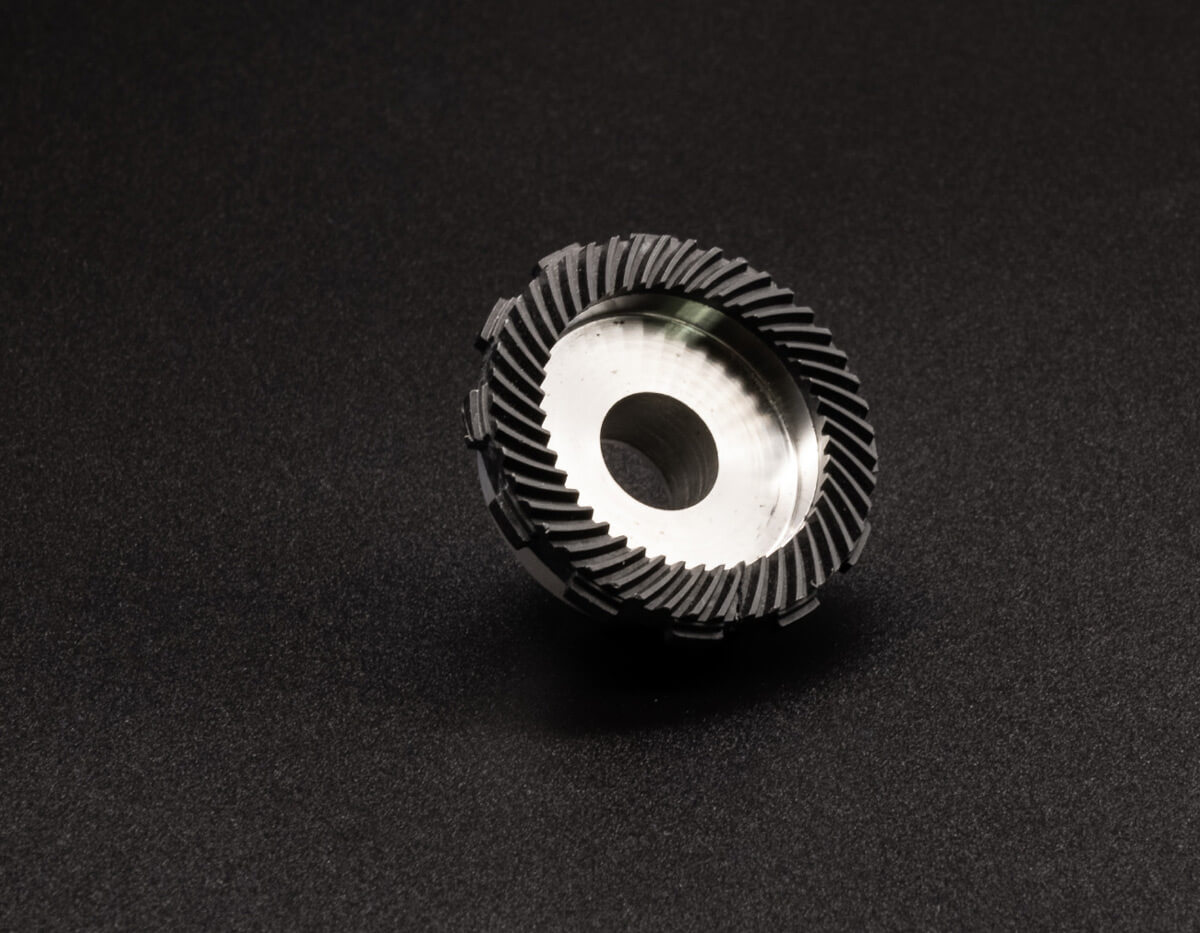

The perfect combination of our excellent knowledge of stamping technology and injection molding technology enables our customers to develop complex plastic-metal assemblies, the so-called hybrid components.

The industrialization and production of hybrid components enable our customers to implement innovative products that are both complex and cost-optimized.

Advantages

Metal and plastics expertise from a single source.

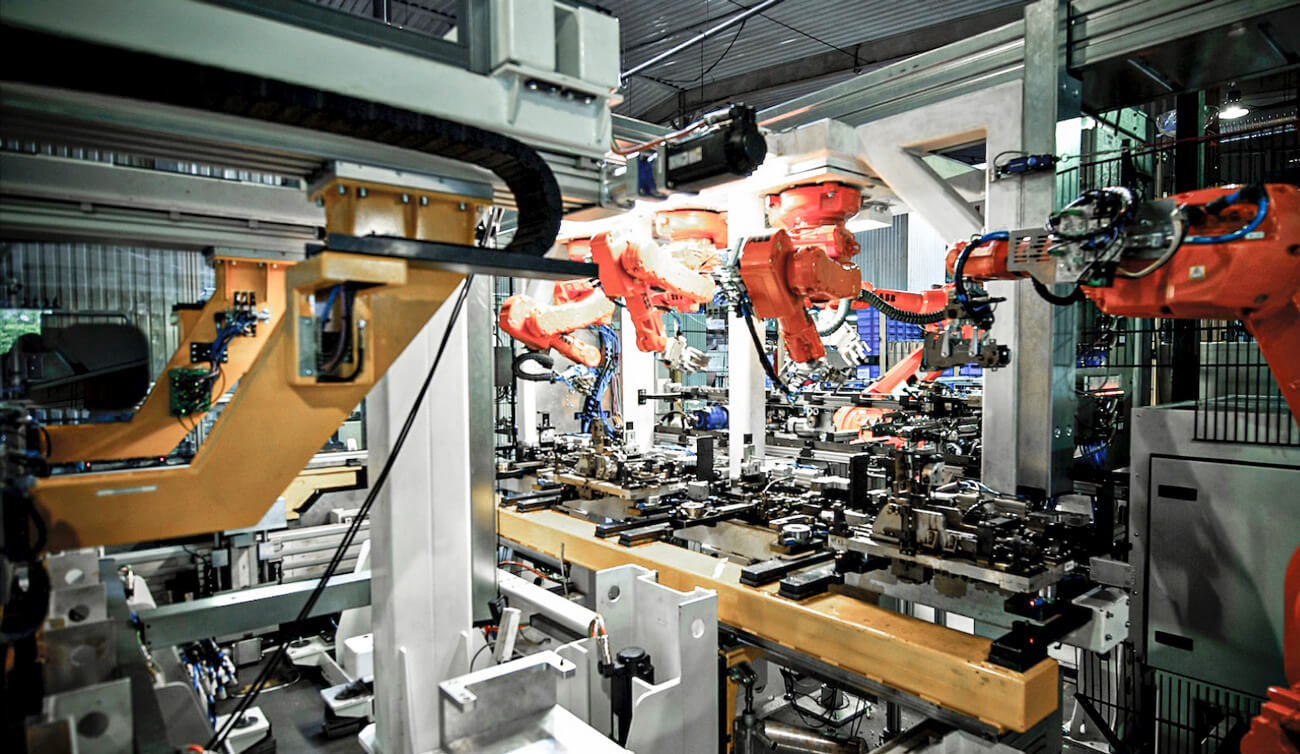

Production automations are available for you.

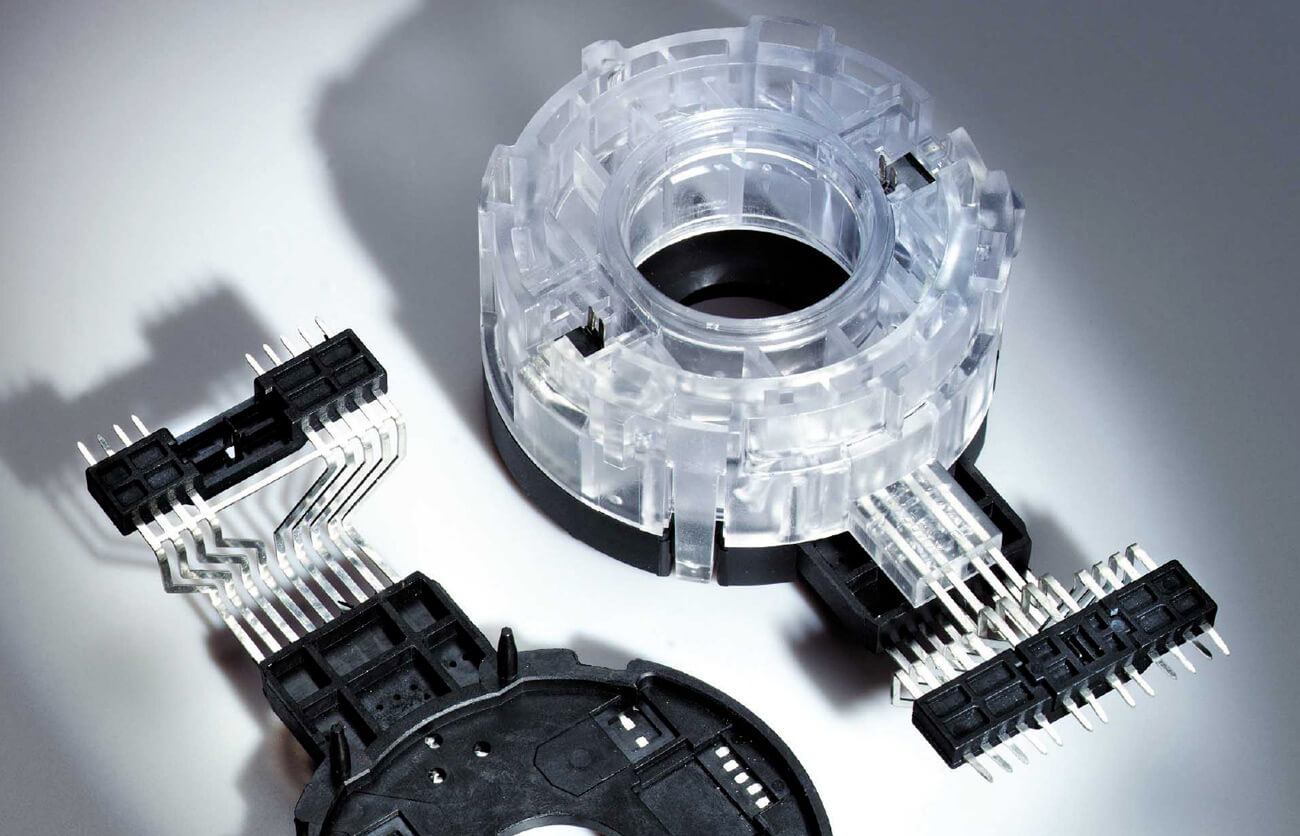

Elopin technology for press fit terminals

Computer tomography during series production

Implementation of cleanliness requirements

HYBRID COMPONENTS ENSURE YOUR SUCCESS! SUSTAINABLY!

By combining multi-component injection molding technology with inline stamping technology and 100% camera monitoring, we reduce complexity and costs!

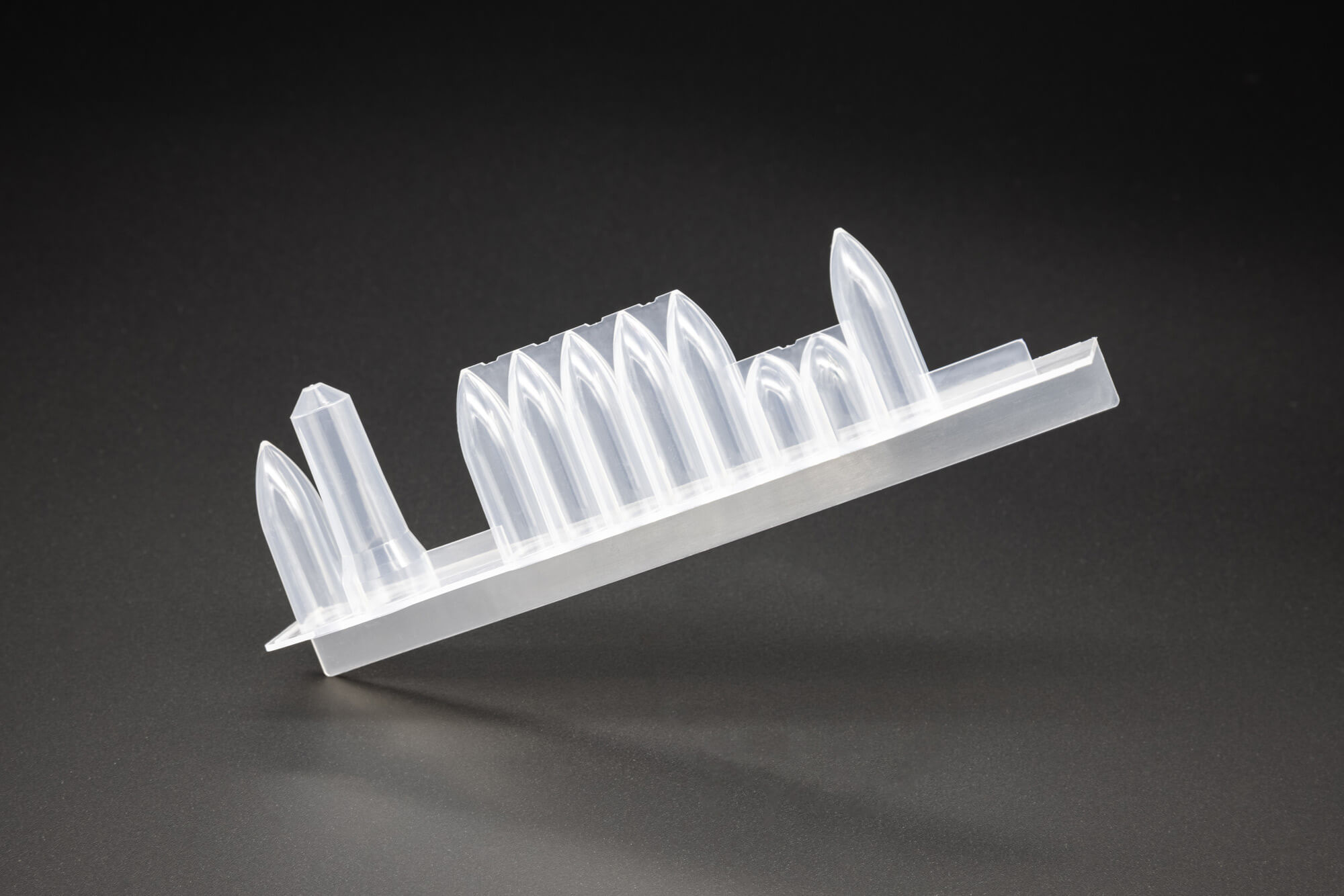

Your hybrid components consist of standard contact overmoldings, Elopin press-fit zones or thermoplastic-TPE combinations with sealing requirements? Our specialists are always available to you to carry out your wishes and start production!

This way, your rain and light sensors, parking sensors, steering wheel applications, transmission units, relay stations, electromobility applications, torque sensors, coilformers, connector strips, contact overmolds and busbars for battery technologies, overmolded stamped grids and much more, can successfully inspire your markets!

Hybrid technology is more than just electromobility!

Our collaboration represents a great asset for ELITech and a nice personal relationship

Nedschroef Herentals counts on Viena International as part of the Rejlek Group as a reliable partner. And as business is looking now, will be counting on them for the future!

Top quality, Professional service, High technical knowledge. 3 top priority goals we expected from our supplier. Viena International as part of the Rejlek Group always match this 3 goals