Apprenticeship at Rejlek – invest in your future

Looking for a career with a promising future? An apprenticeship at Rejlek is the perfect opportunity to gain experience in sustainable production technologies, get to know the fields of mechatronics & toolmaking and foster and refine your own talents. In this article, we explain what prospective apprentices can look forward to, what to expect during the training years and what future perspectives they will have with an apprenticeship diploma under their belt.

WHAT ARE THE ADVANTAGES OF AN APPRENTICESHIP AT REJLEK?

The Rejlek Metal & Plastics Group has been training apprentices since its very beginnings. There are 10 young people in the company at any given time in the Vienna location alone, training to become mechatronics engineers (with the core module of manufacturing technology) and toolmaking technicians, or completing a dual apprenticeship in metal technology and plastics process engineering. The number of talents who have completed their training and are now successful in their careers clearly indicates this, but the benefits of an apprenticeship at Rejlek go much further.

CHALLENGED & PROMOTED

As a family business, we greatly value team spirit, personal responsibility and commitment, as well as a friendly atmosphere within our company. Our apprentices benefit from this in a particular way, as they can develop in an atmosphere of appreciation and challenge, are allowed to make their own mistakes and in the process can learn from each individual member of staff, irrespective of the specialisation they have chosen.

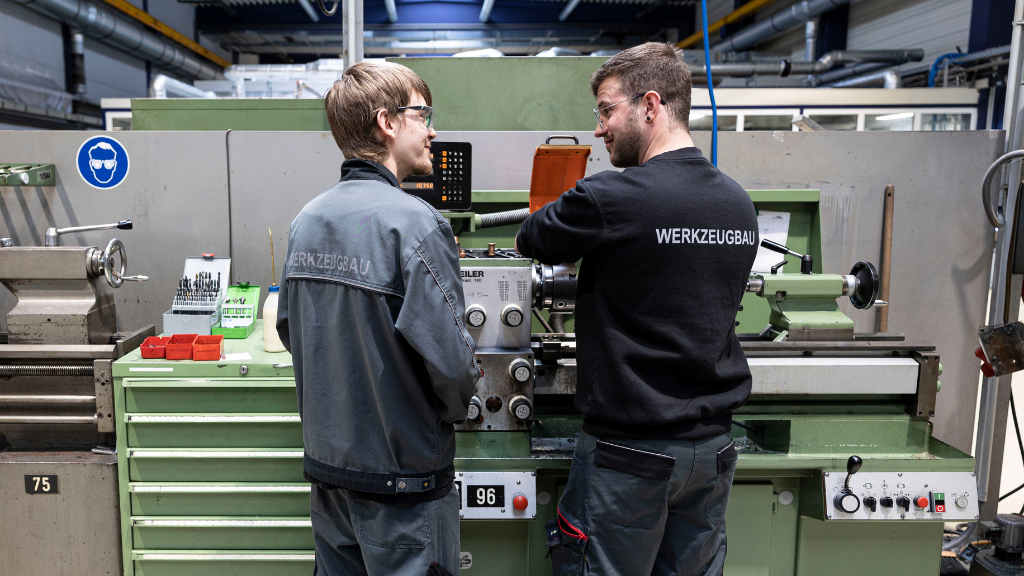

OUR OWN APPRENTICE WORKSHOP

Our in-house apprentice workshop, which we recently refurbished, additionally provides a dedicated space for the young talents to develop and pursue their professional training to become excellent skilled workers in the best possible environment. This facility has its own CNC and NC machinery available for the apprentices, and there they are supervised and guided by a training teacher. A specialised technical instructor also additionally supports them once a week to advance on theory and to familiarise them with special areas even more profoundly than is deemed necessary at the vocational school.

MEANINGFUL CHALLENGES

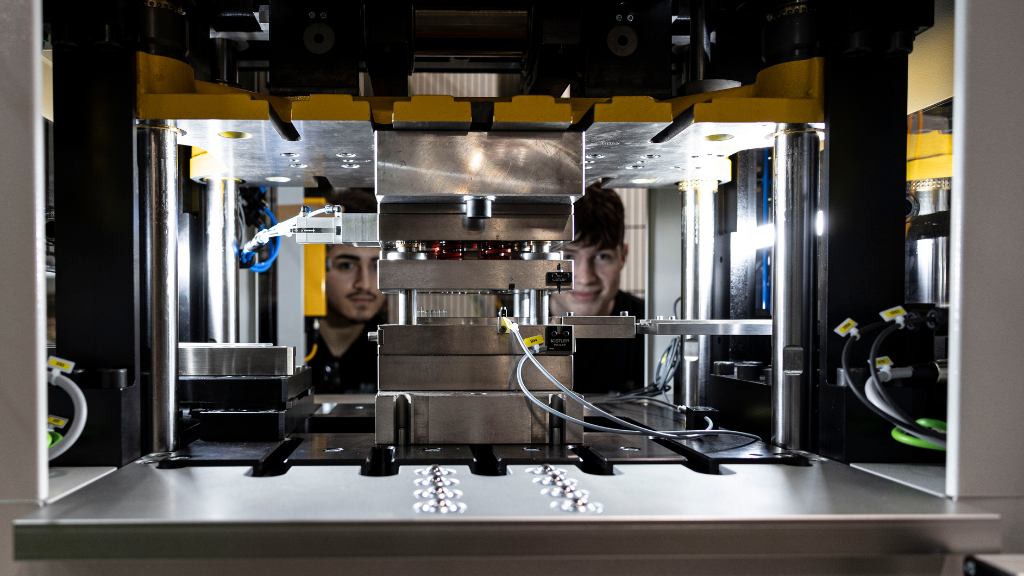

Due to the numerous industries in which Rejlek’s high-end commissioned projects are used, our apprentices gain versatile experience as well. Ranging from medical technology to mobility solutions and the domestic appliances industry to machinery manufacturing, apprenticeships at Rejlek allow young people to work on a variety of different challenges and make a valuable impact on the future’s solutions.

THEORY, PRACTICE, RESPONSIBILITY: THE CURRICULUM IN DETAIL

Time passes easily when one is having fun. That also applies to the apprenticeship and especially here with us in our company. In the first two years of the traineeship, all of our young talents first acquire the basic skills of mechanical production, the foundation for the rest of their apprenticeship. More specifically, the programme includes learning conventional milling, turning and sanding, as well as wire cutting, die-sinking EDM and other CNC-supported production technologies for the budding metal technicians.

Once the milling exercises have been completed after several weeks, the apprentices at Rejlek can already work in the factory in a fully productive manner and can demonstrate their talent and the skills they have acquired on the various components for new tools – but there is never any pressure on them in terms of time; our main focus is rather on conveying a clear understanding of each individual work step. In the second year of the apprenticeship, after getting to know all the machines, workpieces are finally produced entirely by themselves.

A clear advantage of the apprenticeship at Rejlek is the fact that almost all activities can be handled internally – from CNC milling, programming, wire cutting, die-sinking EDM and grinding to engineering, QA and manufacturing. Because of these comprehensive in-house capabilities as well as the design of the apprenticeship at Rejlek, we are able to offer a diverse and varied apprenticeship period to those interested, allowing them to collectively learn the basic skills in manufacturing – and then move on to the specialisation of their choice.

WHAT HAPPENS AFTER THE APPRENTICESHIP?

The journey is far from over after the apprenticeship diploma is obtained. On the contrary: the adventure really accelerates now, for Rejlek offers its trained apprentices a seamless transition into the company. This is a win-win situation for both parties, as specialisation in the complex vocational areas in which we offer training usually does not come until the end of the apprenticeship period. Joining the company immediately after the apprenticeship not only provides valuable experience, but also ensures that what has been learned is deepened and solidified. As a company, we are of course particularly proud when young people, in whose future we have invested, want to continue their journey here with us after completing their apprenticeship.

CONCLUSION: THE FOUNDATION STONE FOR A RELIABLE FUTURE

The benefits of an apprenticeship at Rejlek are incredibly wide-ranging. We place utmost priority on ensuring that our up-and-coming talents are well taken care of and we provide them with training to the very highest standards. To achieve this, we spare no expense or effort, because every single apprentice at Rejlek is a valuable part of our company.

Were we able to inspire you and are you interested in an apprenticeship in the fields of mechatronics, metal technology or plastics process technology at Rejlek? Send us your application directly or visit our exhibition stand at the “Tag der Lehre XXL” (Apprenticeship Day XXL) from 18th-19th October in the Marx Halle in Vienna. We would be delighted to welcome you to our family business very soon.