Prototyping at Rejlek: From the idea to the model

“And there is a magic in every beginning” – what Hermann Hesse so poetically formulated also applies to series productions. The early stages of development harbour a great deal of potential – it is a time of curiosity, questioning and aha moments. It is no coincidence that prototyping and small series production are essential phases that receive a lot of attention. Read on to find out which technologies are used, what to look out for and how we at Rejlek support the development process.

What is meant by prototyping and small series?

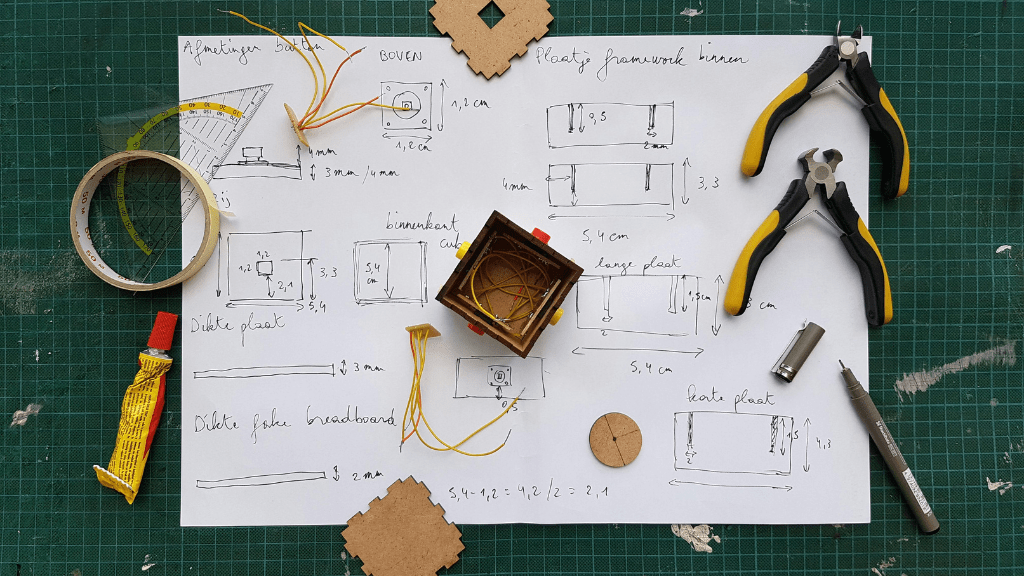

It all starts with an idea: no matter what it is, a lot of time has to be spent planning and experimenting before you can start mass-producing a new product. A well thought-out concept and individual material tests ultimately lead to the first prototype. The path to this point and onwards to series production is often a long one and full of challenges, setbacks and adjustments.

Why is prototyping or pre-production in small series so important? It enables early feedback rounds that reveal problems or change requests. Prototyping can be seen as a kind of learning process that is not about perfection, but about trying out different variants and even appreciating mistakes. This is the only way to recognise how things can be done better.

The nuts and bolts of prototyping

Especially when prototyping with plastics and metals, it is important to understand which manufacturing techniques are particularly suitable in order to proceed cost-efficiently without having to compromise on flexibility and individual requirements. Popular technologies for the production of prototypes and small series include, for example

- Selective laser sintering: This additive process uses laser beams to produce three-dimensional moulds from polyamide powder. Selective laser sintering is extremely popular in rapid prototyping as it is particularly cost-effective and even highly complex geometries can be produced.

- Stereolithography: Another additive manufacturing option in which precise models can be produced on the basis of CAD data. For this purpose, liquid synthetic resin is cured layer by layer with a UV laser, which not only makes it possible to realise highly precise designs, but also scores points with smooth surfaces and versatile material properties, isotropy and waterproofness.

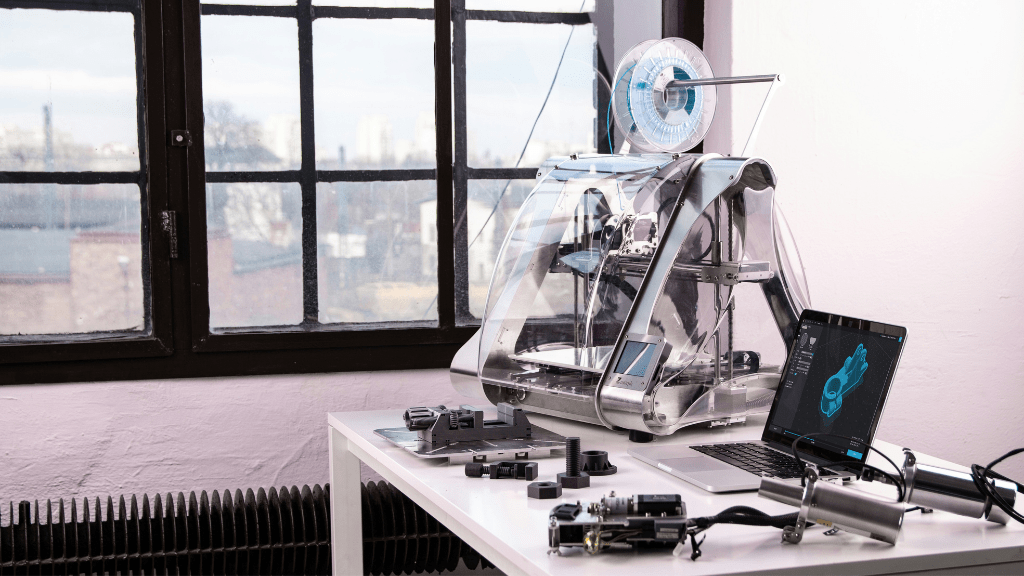

- Multi Jet Fusion: The industrial 3D printing process is similar to laser sintering, as it also works with polyamide. However, no laser is used – instead, the individual layers of the product are cured using an infrared energy source. The main advantages of this technology are the high strength and therefore resilience of the components as well as the fast and cost-efficient realisation.

- Fused Deposition Modelling (FDM®): This patented 3D printing technology has been a proven process in rapid prototyping since the late 1980s. The plastic used is melted in wire form using a hot nozzle and then moulded into the finished product layer by layer. Melt layering is particularly characterised by the production of extremely resilient and durable components with thin walls.

In addition to those mentioned, there are of course many other technical options for realising your prototypes and small series. A good provider will discuss the respective techniques with you in detail to explain the advantages and select a process that suits your needs.

Prototyping with the Modelshop Vienna

At Rejlek, we have specialised in the development of prototypes, small series and special series with our in-house Modelshop Vienna. Here, customers can find a wide range of possible technologies as well as detailed advice from our experienced team. As the production of functional parts made of plastic and metal – or even a complete assembly – takes place directly on site in Vienna’s 23rd district, valuable time and therefore money can be saved.

Our services at a glance:

- Rapid prototyping and prototype construction

- Consulting & Engineering

- Small series in 3D printing

- Design (CAD/CAM)

- Design models and mock-ups

- Small series in rapid tooling

As a rule, our customers already have material ideas and 3D data for their components before the first meeting. However, if you still need input here, we are happy to draw on our immense wealth of experience and find a customised solution together. Basically, the earlier we are brought on board for projects, the better we can contribute our expertise and help make your projects a success.

Conclusion: Small series, big impact

Whether it’s the very first prototype or the first run of a small series, the early stages of product development are the time to test different options, eliminate defects and ensure that your finished product can also be manufactured economically and flawlessly in larger quantities. There are a number of approaches, technical options and materials to choose from, and the expertise of a proven supplier will more than pay for itself.

Are you looking for a reliable and experienced partner for prototyping and small series? Arrange a consultation for your upcoming project now, we look forward to hearing from you.