Why Plastics are the Future of the Automotive Industry!

Several decades passed before the car was suitable for mass production. Much has happened from Carl Benz’s first registration in 1886 to Ford’s mass production from 1903, and the development before that took even longer. The current change from combustion engines to other more sustainable drives, certainly will do!

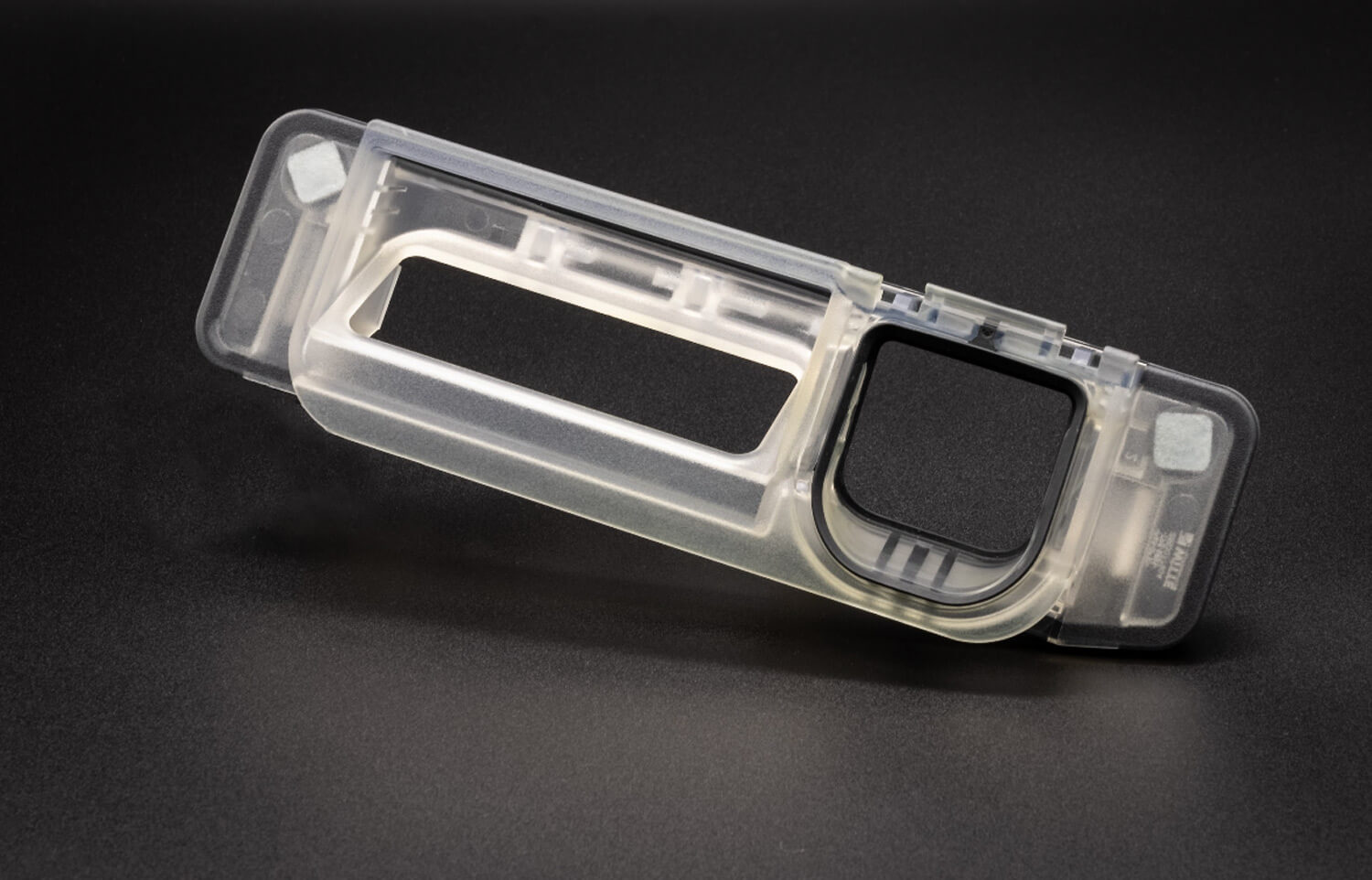

The electric motor is perhaps not the end of the line, but an important part of the ongoing development process. We, the Rejlek Metal & Plastics Group, want to be part of this development and therefore have been involved in battery component production for some time!

But the future does not only lie in the battery segment. Yes, the biggest challenge of battery driven vehicles is still the battery range and will probably remain so in the near future. But in addition to developing and improving batteries, there is another way to tackle this range problem: weight. The lightweight construction in the automotive industry is an increasingly important issue as steel and glass are far heavier than several similarly strong plastics! Polycarbonate, for example, is lighter, insulates better and can be produced to be transparent, i.e. for a pane. Car seats are already made of plastic in most cases to save weight. But in addition to surfaces in the vehicle interior, control elements, trim, engine components and lighting technology, structurally relevant components made of plastic could also be conceivable in the future. Therefore, there are many possible directions in which the development could go!